How to Manage Inventory as You Build, Launch & Grow Your Business

When anyone mentions inventory management, we imagine an employee taking stock in a backroom or painstakingly updating a complex Excel spreadsheet.

These scenarios are not too far from the truth.

Early stage entrepreneurs are focused on creating demand; they use Excel to keep track of pre-sold goods and suppliers. Growing brands look to automate and optimize. Large enterprises make operational excellence a company-wide responsibility from the supply chain to accounting to human resources to sales and marketing.

Ecommerce merchants and business owners face operational challenges at each stage of the business development process, including manual error-prone order management, unpaid vendor invoices, lofty sales projections, lack of demand forecast, and excess labor and materials. Among these, inventory management is most critical for any goods-based company.

Inventory equals cash.

High demand for your products but an insufficient amount of stock could mean losing customers to competitors. Too many products and not enough sales means losing money. Unsold goods also means you have to pay for storage and security, holding up your cash flow.

With any type of business, cash is king. It’s your lifeblood. The best way to optimize cash flow is through efficient inventory management.

Table of Contents

What is Inventory Management?

Inventory management is a systematic approach to obtaining, storing, and profiting from non-capital assets (like raw materials and finished goods). The right stock, at the right levels, in the right place, at the right time, and at the right cost.

Retail is the broadest catch-all term to describe business-to-consumer (B2C) selling. There are essentially two types of retail, separated by how and where a sale takes place:

- First, online retail (ecommerce) where the purchase takes place digitally

- Second, offline retail where the purchase is physical through a brick-and-mortar storefront or a salesperson

Wholesale, on the other hand, refers to business-to-business (B2B) selling. Knowing the differences and best practices of retail and wholesale is critical to inventory success.

Most businesses maintain inventory across multiple channels as well as in multiple locations. The diversity of retail inventory management adds to its complexity and drives home its importance to your brand.

Before digging into strategies and techniques, let’s take a look at some inventory management basics for beginners; a refresher on terminology and formulas.

Inventory Management Terminology

- Barcode Scanner: Physical devices used to check in and check out inventory at in-house fulfillment centers and third-party warehouses

- Bundles: Groups of products that are sold as a single product: Selling a camera, lens, and bag as one SKU

- Cost of Goods Sold (COGS): Direct costs associated with production along with the costs of storing those goods

- Deadstock: Items that have never been sold to or used by a customer (typically because it’s outdated in some way)

- Decoupling Inventory: Also known as safety stock or decoupling stock; refers to inventory that’s set aside as a safety net to mitigate the risk of a complete halt in production if one or more components are unavailable

- Economic Order Quantity (EOQ): EOQ refers to how much you should reorder, taking into account demand and your inventory holding costs

- Holding Costs: Also known as carrying costs; the costs your business incurs to store and hold inventory in a warehouse until it’s sold to the customer

- Landed Costs: These are the costs of shipping, storing, import fees, duties, taxes and other expenses associated with transporting and buying inventory

- Lead Time: The time it takes a supplier to deliver goods after an order is placed along with the timeframe for a business’ reordering needs

- Order Fulfillment: Complete lifecycle of an order from the point of sale to pick-and-pack to shipping to customer delivery

- Order Management: Backend or “back office” mechanisms that govern receiving orders, processing payments, as well as fulfillment, tracking, and communicating with customers

- Purchase Order (PO): Commercial document (B2B) between a supplier and a buyer that outlines types, quantities, and agreed prices for products or services

- Pipeline Inventory: Any inventory that is in the “pipeline” of a business’ supply chain — for example, in production or in shipping — but hasn’t yet reached its final destination

- Reorder Point: Set inventory quotas that determine when reordering should occur, taking into account current and future demand as well as lead time(s)

- Safety Stock: Also known as buffer stock; inventory held in a reserve to guard against shortages

- Sales Order: A transactional document sent to customers after a purchase is made but before an order is fulfilled

- Stock Keeping Unit (SKU): Unique tracking code (alphanumeric) assigned to each of your products, indicating the style, size, color, and other attributes

- Third-Party Logistics (3PL): Third-party logistics refers to the use of an external provider to handle part or all of your warehousing, fulfillment, shipping, or any other inventory-related operation. Fourth-party logistics (4PL) takes this a step further by managing resources, technology, infrastructure, and full-scale supply chain solutions for businesses

- Variant: Unique versions of a product, such as a specific color or size

Four Inventory Management Formulas

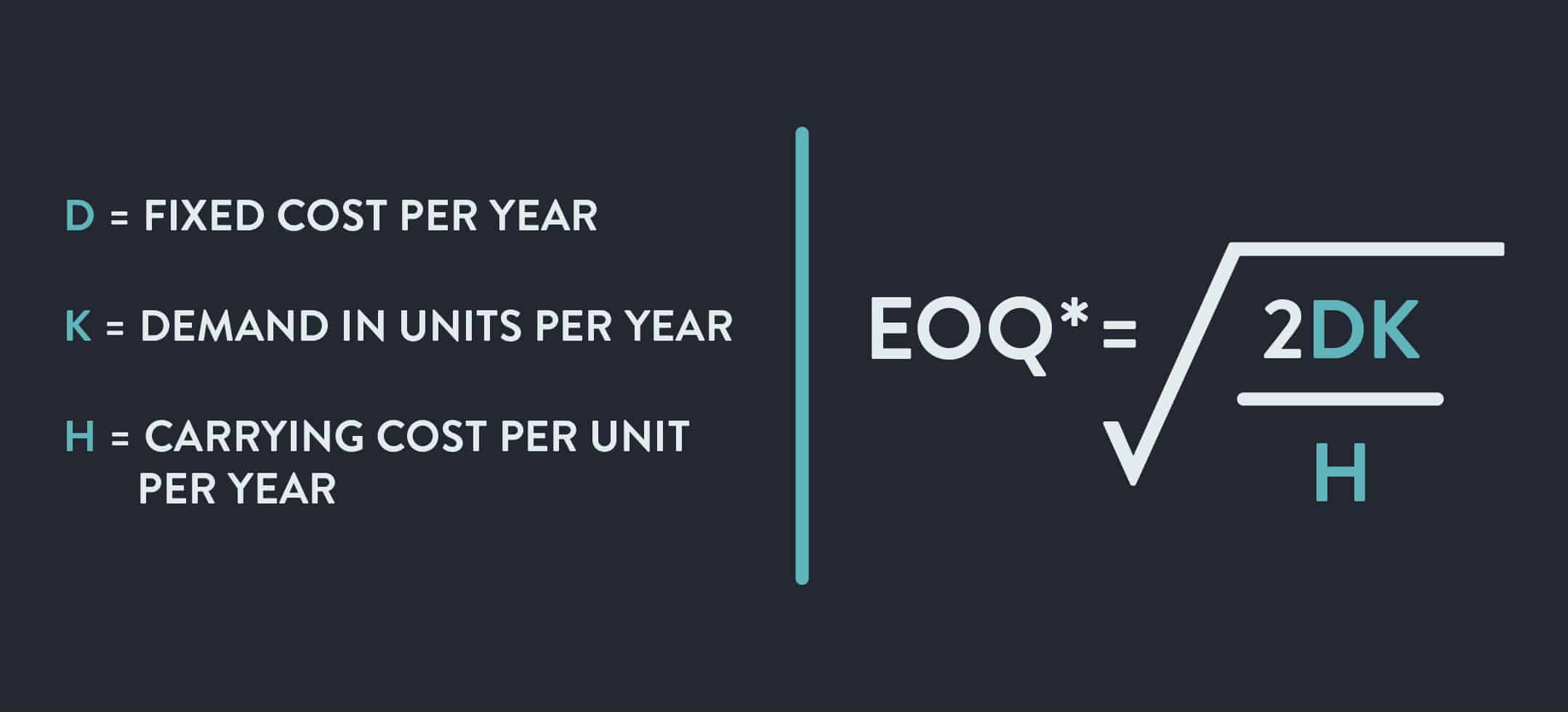

Formula #1 Economic Order Quantity (EOQ) Formula

Your EOQ is the optimum number of products you should purchase to minimize the total cost of ordering or holding inventory. Figuring out your EOQ can potentially save you a significant amount of money.

EOQ = √(2DK / H), or the square root of (2 x D x K / H)

Where:

- D = Setup costs (per order, generally includes shipping and handling)

- K = Demand rate (quantity sold per year)

- H = Holding costs (per year, per unit)

Formula #2 Days Inventory Outstanding (DIO) Formula

Days Inventory Outstanding (DIO), also known as Days Sales of Inventory (DSI), refers to the number of days it takes for inventory to turn into sales. The average inventory days outstanding varies from industry to industry, but generally, a lower DIO is preferred.

Formula #3 Reorder Point Formula

The reorder point formula answers the age-old question: When is the right time to order more stock? Calculating your reorder point takes three steps:

- Determine your lead time demand in days

- Calculate your safety stock in days

- Sum your lead time demand and your safety stock

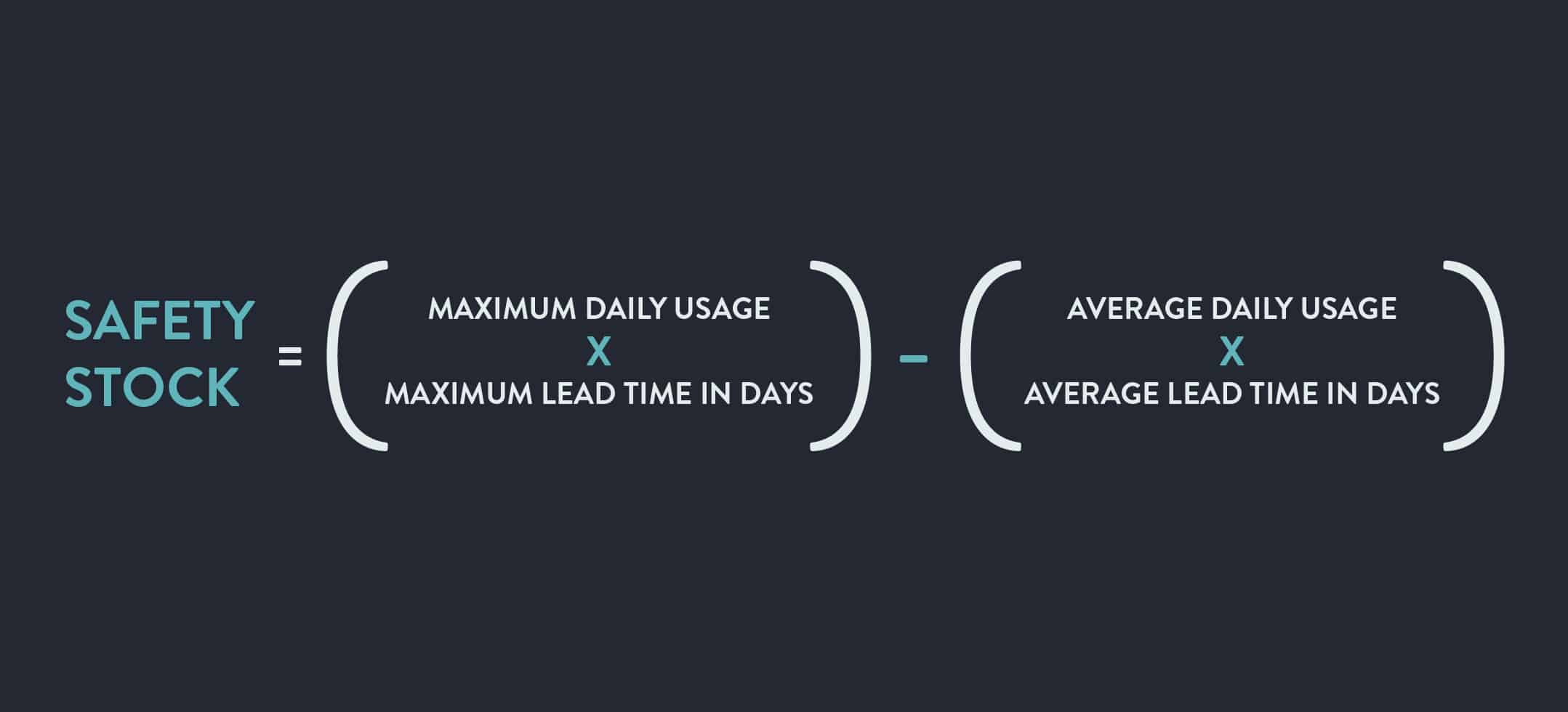

Formula #4 Safety Stock Formula

Safety stock acts as an emergency buffer you can break out when it looks like you’re on the verge of selling out. You want to have enough safety stock to meet demand, but not so much that increased carrying costs end up straining your finances.

While this sounds like common sense, the trick is to decide on how much safety stock to carry:

- Multiply your maximum daily usage by your maximum lead time in days

- Multiply your average daily usage by your average lead time in days

- Calculate the difference between the two to determine your safety stock

Operational Considerations

Your business will have varying needs and face challenges at every stage of business development. We’ve outlined operational considerations, brief case studies, and recommendations to survive and thrive at each stage — from build to launch and growth — of your business.

The Build Stage

An idea is born. You could start your entrepreneurial journey by dropshipping as a means of market research. This strategy allows you to offer a wide range of products without actually purchasing and storing inventory. In a few months, some entrepreneurs discover enough consumer demand to warrant its own spin-off, branded product.

With this validation, a crafty DIYer could develop a prototype and either create a small batch of products either in-house or with a manufacturer.

Making your own products allows you to enjoy relatively low production costs, which for many ecommerce businesses, can make up the bulk of their startup costs. It also gives you full quality control over your product and business agility to adjust to demands and specifications. However, production volume is limited to your skills and resources, and leaves you with less time to work on other aspects of your business.

Those who are confident in the product’s marketability, but not in their own maker skills, would outsource the prototyping work to a vetted manufacturer. Doing so helps early-stage entrepreneurs achieve the greatest margins over dropshipping or purchasing wholesale. But it poses the highest risk since manufacturers require a minimum number of orders — an unavoidable startup cost. The process of prototyping, sampling, refining, and final production also takes a long time; further amplified by differences in languages, cultures, and time zones — should you choose to outsource this overseas.

At this stage, many entrepreneurs pre-sell goods to generate awareness with early adopters, who take pride in having a product-in-hand that’s brand new, different, and compelling. If their belief in your product is strong, they can be your greatest advocates but also your harshest critics.

Hear them out and keep the lines of communication open. Give them the platform to share feedback, which will be valuable for the next iteration of your product. Use their comments to make the necessary modifications before a public launch.

Next, keep your ideal customer in mind. What problem do they face that you’re solving? What should they expect when using your product? Do they already use similar products? Which ones and why? Can your product do a better job? What demographic data can you glean? What do they prefer or dislike? Where do they shop?

This exercise will help you create a buyer persona, making building a brand easier. For example, if you’re creating a men’s grooming line, you may avoid a pastel color palette or childlike icons. If you learn that your ideal customer (moms-to-be) want to be seen as stylish, you’d invoke that in your brand photography and content. A properly researched buyer persona will help you create a brand that connects effortlessly with your ideal customer.

Introduction of your product to the world will take time and the size of the market for the product is small. This means sales are low and tend to be slow so it’s important to keep inventory levels relatively low as you work with suppliers, ones who are flexible and can facilitate rapid prototyping at an affordable cost. This will be essential to your early success.

Conversely, the cost of things like research and development and marketing can be high, especially in a competitive niche.

At this stage, it’s common to use an Excel spreadsheet to manage purchase orders, inventory, and keep track of vendors. There are many free inventory templates available online, find the one that works for you. If you know how to utilize it correctly, you can generate a variety of highly valuable inventory formulas that will help you keep track of stock, sales, purchase orders, vendors and more.

Excel does have its disadvantages, especially when your business starts to expand. But, if you have a limited number of products and sales channels, trust yourself to double check figures as you put them in, have the available time, and need something that is simple and cost-effective, Excel does the job well.

The Launch Stage

Time for lift-off! Your product is now available for purchase. But, just because you build it, doesn’t mean people will come. You must create demand.

To jumpstart brand awareness, entrepreneurs engage in a combination of strategies including media relations, direct mail, influencer marketing or celebrity outreach. Others turn to digital marketing (for example: PPC, SEM, social media ads) to direct a steady stream of online visitors to their ecommerce store. If set up correctly and optimized over time, those site visitors should quickly convert to customers.

Direct-to-consumer (DTC) brands have upended traditional marketing by taking advantage of the millennial audience’s sharing habits on social media. Rent the Runway, for example, encourages customers to post photos of themselves wearing dresses, which are integrated with each product page. Seeing photos of real women of different shapes and sizes is a powerful marketing incentive for those still on the fence about renting a dress.

What about launching your own popup shop or placing your product in a popup showroom? Instead of carrying physical goods, these spaces often feature highly attentive, iPad-toting staff to help drive shoppers into their ecommerce experience for detailed product information and the opportunity to purchase. It’s a noteworthy strategy that successfully captures valuable customer data, and helps you further nurture relationships for the long-run.

Preparation is key. At this stage, start small with your first production run. Maintain low inventory levels and increase as the demand grows. Consider how orders will be fulfilled, shipped to customers or delivered on-site to brick-and-mortar vendors.

Think about your current systems and processes. Can your spreadsheet keep up?

Honest Brew first started with a spreadsheet calendar containing all of their customers’ names to manually keep track of inventory and subscription terms. Forecasting and growth metrics were based purely on estimates. It wasn’t long before Honest Brew cringed at the bitter taste of manual operations. They needed up-to-date visibility and control over their inventory, SKUs, purchasing processes and invoicing.

If you are spending too much of your time in Excel, or dread doing weekly stock takes, you might want to upgrade your system to a dedicated inventory management solution. Not only will it automate a lot of manual, time-consuming tasks, but it will also allow you to integrate all your tools together to assist with everything from procurement to fulfillment. The work will only increase from here on out.

As global demand for your product increases, so too will your transportation and labor costs, risks, and expectations for world-class service. You’ll need to consider managing stock and inventory efficiently across multiple warehouses.

The need for an additional warehouse or two is not limited to just multinational businesses, but also considered by companies operating in fragmented regions, hard-to-reach places or areas with limited logistics. Other business owners want to have backup warehouses covered by premium insurance plans for just-in-case or worst-case scenarios (for example: flooding, fires, earthquakes, etc.).

The Growth Stage

Now you’ve got an effective marketing plan, a stable stream of orders coming in, considering larger premises, and increasing your labor force.

Congratulations! These are all healthy signs of business growth.

You may not want to hear it, but there are downsides to such meteoric success. Most businesses fail at this stage because they’re not set up for sustainable growth.

It’s time to optimize your processes and automate activities to boost your sales and net margins. You’ll also need to manage different types of inventory for maximum profit and the lowest cost. But would you know how?

With ABC Inventory Analysis and Management, you can view your inventory from the perspective of best-selling to least-selling, as well as lowest inventory costs to highest. It’s an inventory optimization approach that assumes not all products are of equal value and more attention should be paid to critical products.

ABC Inventory Analysis also allows you to do strategic pricing that could positively impact profitability, forecast demand, and set customer service levels that gives precedence to class A high-value customers.

While there are no hard-and-fast rules for dividing products, categories typically look something like this:

- A Items : 20% of products, which accounts for 70% to 80% of consumption value

- B Items : 30% of products, which accounts for 10% to 20% of consumption value

- C Items : 50% of products, which accounts for up to 10% of consumption value

This model can be adjusted to suit different types of products and businesses, with the key focus being identifying and nurturing top sellers to drive higher profitability.

As we mentioned earlier, you may consider hiring more people to keep up with growing complexity and high-volume sales. But without the proper tools and systems in place, mistakes will be made and these errors will compound over time.

Businesses under $1M spend over 90 hours on inventory management, product sourcing, and managing purchase and sales orders every month. The process of order management is much more complex than simply taking sales orders and filing them. When you break it down, what it truly represents is a cascade of events that ripple through your organization affecting its entire operational ecosystem. Within it includes the need to:

- Receive and track sales orders

- Forecast future potential demand

- House and maintain customer data

- Update multiple sales channels in real time

- Fulfill orders accurately and in a timely manner

- Process payments in multiple currencies and update accounting ledgers

- Track, monitor, update, and replenish (or manufacture) inventory

And, on top of all that, continue to run a flawless sales and marketing operation.

By optimizing and automating the back-end of your business and implementing an order management system, you’ll finally be able to win back the time that was being stolen by manual or inefficient workflows.

A robust inventory and order management solution will also help you avoid the common fulfillment pitfalls: Stockouts, manual and error-prone reconciliation, capital insufficiency, and decreased customer satisfaction.

It will also provide you with real-time visibility into orders and inventory levels, forecast demand, and integrate with your tools, warehouses and third-party logistics partners for a seamless fulfillment process.

Conclusion

To truly grow and expand your business, re-examine the foundation upon which it’s built upon and the systems that you’ve selected to support it. But you shouldn’t wait until the later stages of your business to explore this. From the very beginning, take note of areas where you can streamline operations, iron out efficiencies, and iterate wins so when the time comes, you’re not simply implementing band-aid remedies but a holistic and integrated system that will help your business thrive in current and future market conditions.