How to Source Products from Chinese Manufacturers

For any ecommerce entrepreneur, one of the first steps is figuring out how to develop your supply chain. You have three options: you can produce products yourself, buy locally, or manufacture abroad. This article will focus on how to source products from Chinese manufacturers, as it is often the most complex and scalable way to grow in ecommerce.

Why Source Products from Chinese Manufacturers?

The truth is, producing products abroad enables your business to have strong margins, and when your gross margin can make or break your business, chances are that you’re eventually going to want to manufacture abroad if you haven’t started already.

Economically speaking, the reason why producing products abroad is so cost effective stems from the value of our currency and the cost of labor. The American Dollar is currently equal to 6.88 Chinese Yuan and 64.47 Indian Rupee.

You can understand why the labor costs are cheap when you know the Chinese factory worker is getting paid an average of $2 USD an hour compared to over $23 USD in America. The cost of living is also much cheaper in China and to exemplify that I often compare the price of bottled water in both countries: 25 cents in China versus 1+ dollar in America.

When you’re looking to produce products like watches or backpacks, labor is your main cost outside of raw material. The cost of labor in countries through Asia is always going to be cheaper than in America.

In this detailed guide to manufacturing products abroad, you’re going to learn the following:

- Types of manufacturers that exist and what to watch out for in each one

- How to efficiently communicate with your manufacturer

I’ll start with my experience in China.

My Background

I started learning about China during my freshman year of high school in 2008 when I was studying the language. Like any student who has studied a language knows, if you really want to learn, you need to go to a country that speaks that language.

By my junior year of high school, I was a full-blown foreign exchange student living in Beijing with a host family and attending a local Chinese high school. I’d bike 15 minutes to school every day wearing my school’s light blue tracksuit uniform, hearing “Lao Wai” (foreigner) with every pedal I took.

In China, especially when you’re one of the only foreigners to wear a local school uniform in a country of 1.3 billion people, hearing the term “Lao Wai” is common. It’s just the way Chinese people refer to foreigners and for the most part, it’s usually a sign of welcoming interest.

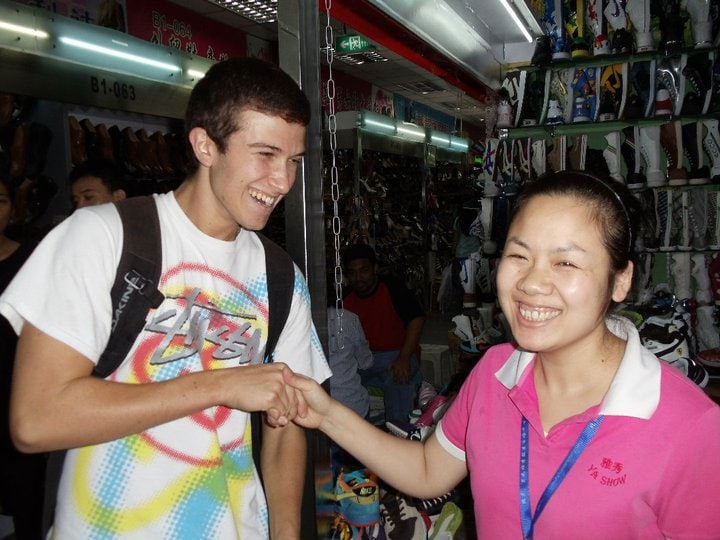

In my year immersed in China, I studied Chinese for four hours a day and became fascinated by the markets in Beijing. In the Ya Show market, as an example, I learned the ins and outs of haggling and when a shopkeeper started with a price of 2,000 Yuan, I tried my best to knock the price down to 300 Yuan.

(Me with a shopkeeper in 2010 after a successful bargain!)

These markets were my stomping grounds and I eventually became friends with some of the shopkeepers who explained the ins and outs of their own supply chains.

Though the goods at all these markets are considered fake, some of them do actually come from the manufacturers that produce the real products. When a manufacturer needs to produce 100,000 identical products, there is no way they can produce that exact amount so each production run will have overruns. Factories will then often sell these additional products on the black market, as their client doesn’t want more than 100,000 of that product.

After my year in China, I became fascinated by supply chains. Since 2010, I have been to China numerous times, brought dozens of products to market, visited manufacturers across the country, and ran a few ecommerce stores of my own.

Enough about me, let’s dive into the types of factories that exist.

Types of Manufacturers

The types of manufacturers in China stem from wholesalers, traders, and actual manufacturers. Between them all, you have sourcing agents that often work off of commissions.

One of the main problems when searching for a manufacturer abroad is navigating through the plethora of middlemen on websites like Alibaba. These wholesalers and trading companies shouldn’t be your go-to source, as they’re taking a cut on top of the actual cost from the manufacturer. Instead, you want to focus your sourcing efforts on actual manufacturers so you can go directly to the source.

Before we dive into how to find an actual manufacturer, let’s first understand how to identify wholesalers, trading companies, and sourcing agents.

Trade Companies

Trading companies usually deal with a wider array of product categories and make money by adding a margin on top of the manufacturer’s price. Most professional purchasers want to go directly to the manufacturer but this isn’t always rational though because if you need a low minimum order quantity, it won’t make sense to work with a larger factory. The larger factory will have higher order quantity requirements and you’ll be a small fish in a big sea, instead of potentially being one of the trading company’s biggest clients.

Figuring out whether you’re dealing with a manufacturer or trading company can be tricky though and some trading companies will blatantly pretend to be a manufacturer when they are not.

Trading companies have distinct implications when you’re sourcing from them:

- It will be harder to assess the factory that will actually be manufacturing your product

- It will be difficult to hold the trading company liable in the case of defective products

- It may be easier for the trading company to “disappear” or otherwise evade communication

Though these scenarios are rare, it is worthwhile to be made aware of.

Wholesalers

This type of business makes money in a similar way to a trader: They buy a product in bulk and then add their margin to the total cost. Wholesalers are common in America and, at my company Sourcify when we help businesses cut costs, it usually stems from them dealing with a wholesaler and not the manufacturer.

Most people deal with wholesalers because they often have foreign representation. They may also have a warehouse in America, meaning your lead time and shipping costs could be reduced. With that said, when we work with clients who have been buying through a wholesaler, we’ve saved them an average of 45%-340%.

As an example, JJ George, a company producing premium grills and grilling equipment, was buying a key component from a wholesaler here in America. They came to Sourcify knowing they were overpaying for this part and wanted to save costs by going directly to the manufacturer. Within a week, we found and introduced them to the manufacturer in China who was producing the part for their wholesaler, saving them 65% of their original cost for this part.

If you’re starting a new ecommerce business, I would recommend avoiding wholesalers because you need that additional product margin to grow.

Manufacturers

When searching for a source, manufacturers should be your target. Going directly to a manufacturer is almost always the best approach, as you’ll have the most profit margin.

The problem lies in finding the right manufacturer to work with and many don’t employ reliable English speaking sales reps. Most the companies you find on Alibaba will be trading companies, as they’re in the business of selling the products they acquire from manufacturers and often employ English speaking sales reps.

How to determine whether you’re communicating with a trading company or an actual Chinese manufacturer

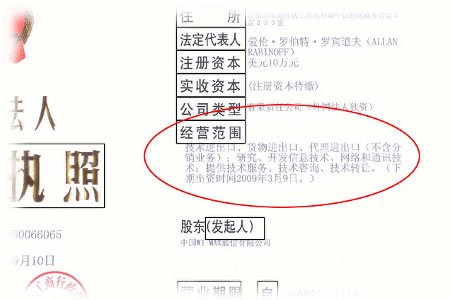

The first step will be to ask for a copy of the company’s business license. The business license will tell you what kind of company you’re dealing with. Once you’ve got a copy of the business license, you’ll need to look at the “Business Scope” label (经营范围 – Jīngyíng Fànwéi). The companies that you’re communicating with should be more than willing to send you their licenses. It should look like this:

The business scope will be a list of categories that the business is legally permitted to operate in. It looks like this on the license:

If you don’t want the company to know that you’re researching them or if you don’t trust the business license they’ve sent you, you need to find the company’s registration record. Starting in 2006 these have been made available online to the general public by the AIC (Industrial and Commercial Administration Bureau) for each province of China.

To find the company’s registration on the AIC website, you need to know which Chinese province the company is registered in. Each province has its own AIC website. As an example, here’s a link to the province of Guangzhou.

Once you’ve found the province’s AIC website, you’ll use the company’s registered Chinese name to search for their record. You can then use this public record to confirm the information shown on the business license or to check a company’s category (trading company or manufacturer) without them knowing.

The flaw of this process for most ecommerce entrepreneurs is that most provinces don’t have English websites so the search must be done in Chinese. With that said, with Google Translate’s Chrome Extension, you should be able to put the pieces together.

Now that you know the difference between the different types of suppliers and how to confirm them, we’re going to dive into ways to effectively communicate with them.

Keys to Communication

Communicating with manufacturers can be the most challenging part of bringing a product to life. You’ll face language barriers and time differences, yet the amount of money you’ll save producing abroad will almost always be worth it.

Having a good relationship with your manufacture stems from clear communication and since relationships can make or break a business in China, communication will be essential to your manufacturing success. (China literally has a term, “Guang Xi,” that translates to the relationship of people in business.

When speaking with your manufacturer, you’re most likely going to be talking to one of their sales reps. I’ve been inside a manufacturer’s sales office and, depending on the size of the manufacturer, it can be filled with cubicle-style desks that are usually manned by a worker with an elementary English level.

(A manufacturer’s office )

Step 1: Communicate Clearly

Manufacturers rarely like speaking on the phone because their English level may not be good enough to speak and their ability to type English is much better, so written styles of communication are usually best.

For that reason, when communicating with them you need to make your sentences as simple as you can. Do not use complex words. Some sales reps will be using a tool similar to Google Translate so making your sentences to the point can save you from missteps.

Complex paragraphs and extended paragraphs will lead to confusion. Make your questions clear and to the point. When asking a manufacturer a set of questions, I’ve learned to list them out in numerical order with one question on each line like the following:

- What is your minimum order size?

- Do you produce product packaging?

- Can I come to visit your factory?

Though these are basic questions, you’re more likely to get a better response by stating your message in an organized way.

Step 2: Have Multiple Ways to Communicate

The next step to confidently communicating with your manufacturer is having multiple ways to communicate. Just as you shouldn’t single-source your products (having no manufacturer to fall back on), you shouldn’t rely on one mode of communication with your supplier.

Email is not enough. You should connect with your manufacturer through at least two or three forms of communication. The most common are email, WeChat, WhatsApp, and Skype.

WeChat is a Chinese-based mobile app that is very similar to Whatsapp. Instead of using a number though, WeChat is username based and users share “Moments” detailing their lives. For most manufacturing sales reps, their WeChat will be full of product photos.

Using WeChat, Whatsapp, or Skype will save you if you are ever in a manufacturing emergency or just want to communicate faster with your manufacturer. Connecting on all three of these platforms also builds a stronger relationship and further confirms that the manufacturer you’re dealing with is legitimate.

Step 3: Have Multiple Contacts

Once you have built a strong relationship with a sales rep, it’s time to dive deeper into the manufacturing team. I always like to know at least two people at a manufacturing company before I do business with them.

This way, if my sales rep doesn’t respond, I can get in touch with my other contact there. A sales rep may not respond for a number of reasons such as going on vacation, getting laid off, or just simply getting lost in communication.

To get in contact with another employee that works at the manufacturing company, simply ask to be introduced to a manager or another sales rep. Your main reason for wanting another introduction can be to confirm information or to have an employee to fall back on. Your sales rep should understand this and be willing to introduce you to other employees at their company.

The best way to have a great manufacturing experience is through constant communication. If I’m scoping a new manufacturer or in a production run, I often touch base with my manufacturer about three-four times a week. This will keep your production run top of mind for your manufacturer.

Conclusion

When you’re manufacturing overseas, it is going to be an ongoing process. Business in Asia is relationship-based and you’re going to need to maintain your manufacturing relationships throughout your product development cycle.

Though language barriers and time zones may cause some setbacks, it’s well worth it when you’re saving on production costs. Once you’ve found a manufacturer who is capable of producing your products and that you trust, it should be full steam ahead towards finishing a production run.

What sets a successful production run apart from the rest is a company’s initiative to engage with a manufacturer while maintaining their relationship. If you’ve been looking to start producing your products overseas, it’s about time you tried. What are you waiting for!