#TheGreatBuild: Make, Manufacture, Wholesale or Drop Ship

Welcome to #TheGreatBuild, a series dedicated to starting an ecommerce business from scratch. In this series, the founder of A Better Lemonade Stand, Richard Lazazzera, shares the lessons he learns and the strategies he tries as he builds his own ecommerce business from the ground up. This series has been created with the intention of showing other new entrepreneurs what it takes to start an ecommerce business so it will hopefully inspire them to start their own online business, too.

To read all the blog posts included in this series, navigate using the Table of Contents down below.

Table of Contents

- #TheGreatBuild: Choosing a Niche & Product to Sell Online

- #TheGreatBuild: Product & Niche Evaluation

- #TheGreatBuild: The Great Reveal of My Product & Niche Selection

- #TheGreatBuild: Make, Manufacture, Wholesale or Drop Ship

- #TheGreatBuild: Negotiating with a Manufacturer

- #TheGreatBuild: Choosing a Shopping Cart

- #TheGreatBuild: Pivoting

- #TheGreatBuild: How to Build a Brand Persona

- #TheGreatBuild: Unveiling My Brand

- #TheGreatBuild: DIY Product Photography

- #TheGreatBuild: How to Launch a Business

- #TheGreatBuild: First Month Revenue & Marketing Report

- #TheGreatBuild: Behind the Scenes of a 6-Month-Old Ecommerce Business

Now that I know what I want to sell — high quality, colorful, and fun men’s dress and casual socks — I need to decide if I am going to make, manufacture, wholesale or dropship them. There are pros and cons to each one of these methods and my choice will partially determine my margins, overall brand control, costs of getting started, and work that will be involved.

The 4 common methods to obtain products are:

- Make

- Manufacture

- Wholesale

- Dropship

It’s important to understand the pros and cons of each of the methods listed above. We will go into more detail for each one below:

Business Model #1: Make

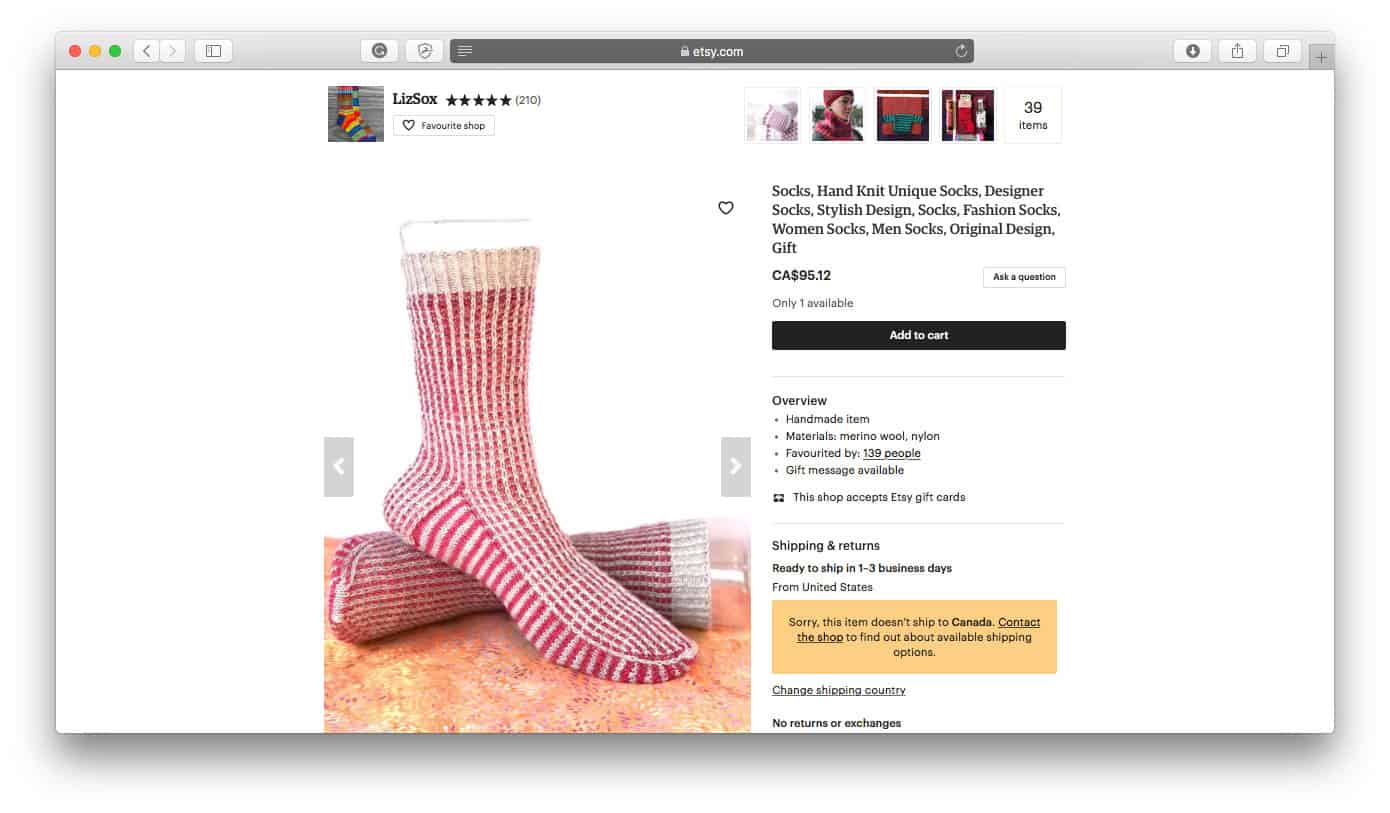

This approach is a common approach among hobbyists. Creating the product yourself allows for the most control over quality and the brand but comes at the cost of time and scalability. The primary product costs in this situation include the purchasing of raw materials and the storage of those materials/inventory, along with any labor and shipping costs.

Low Risk: A big bonus of making the product yourself if that there are no minimum order quantities (MOQs) like you would have if you ordered from a manufacturer. You can make the products as you receive orders allowing you to easily get the business up and running, proving your concept before investing too much time and energy into it.

Etsy, an online marketplace for self-made goods, can be a great place to start and prove your model if you are capable of making the product yourself.

Branding Options: If you make a product yourself, you only have the option of building your own brand.

Example: LizSox on Etsy

Business Model #2: Manufacture

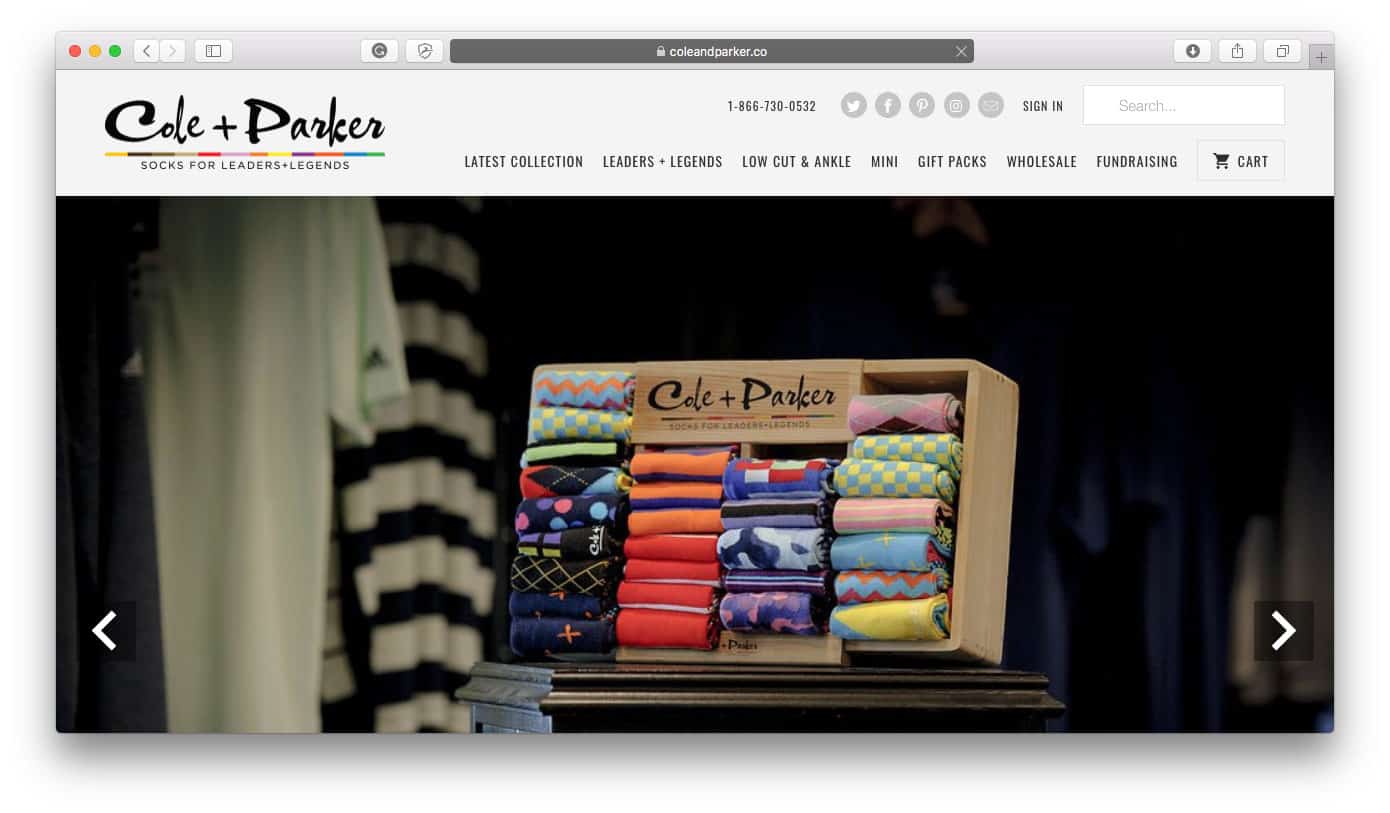

You can purchase the product directly from a manufacturer. There are various sites to help you source a manufacturer from all over the world and it’s much easier than you probably think. I recommend that you check out our Manufacturer Directory to find a curated selection of manufacturers based in North America, plus our Alibaba Review to learn more about sourcing from overseas suppliers.

Purchasing products from a manufacturer is a great option if you want to create your own brand or just want more control over your product and customer experience. Many products from manufacturers can be re-branded (referred to as private labeling) allowing you to create your own brand and stand out from the competition.

High Risk: Obtaining your product by purchasing from a manufacturer is the highest risk option. You must purchase inventory upfront with no guarantee it will sell. Manufacturers generally have an MOQ (minimum order quantity) so you will likely be starting out with a sizable number of units. MOQs vary depending on the product and manufacture so make sure you discuss early on what the manufacturer’s MOQ is.

Risk also comes in the form of fraud if you are purchasing from a manufacturer overseas, particularly from Asia. Sites like Alibaba do have safeguards in place to help prevent fraud but it is still a very real issue. If you do intend to use a service like Alibaba to find a manufacturer, make sure you check out our Ultimate Guide to Safely Sourcing a Product from Alibaba and our article on How to Source Products from Chinese Manufacturers.

Branding Options: Just like making your product, if you manufacture your product you also are going to be building your own brand.

Example: Cole & Parker

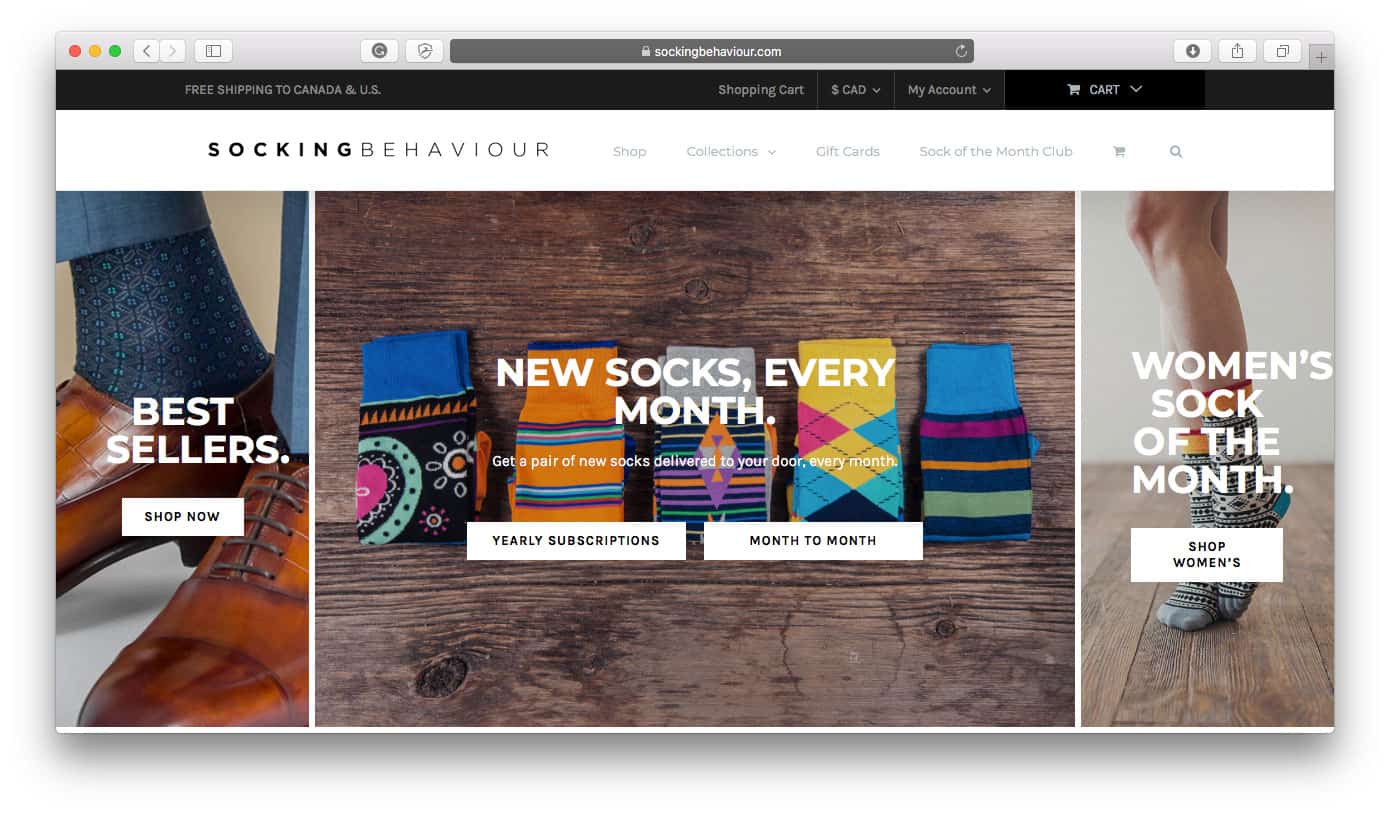

Business Model #3: Wholesale

Wholesaling is a fairly simple and straightforward process. You are essentially buying your product (another brand’s product) from the manufacturer directly or from a middleman wholesaler at a discount, which you then resell at a higher price. Although wholesale rates aren’t set in stone, they typically have a 50% margin. For comparison, dropshipping usually only has about 20% margins.

Wholesaling is a good option if :

- You want to get up and running quickly

- You don’t want to create your own brand for your products

- You want to sell another brand or many different brands

Medium Risk: Wholesaling is a lower risk business model vs. manufacturing for a few reasons. First, you’re dealing with brands that are usually already validated on the marketplace so you don’t waste time and money developing a product no one wants. Also, you usually don’t have to purchase as high of a quantity compared to manufacturing your own product. To find suppliers of wholesale products, check out our Wholesale Suppliers Directory.

Branding Options: Wholesaling usually involves selling other brands but you will be selling it under your website’s brand. Sometimes, other brand manufacturers will allow you to do private label packaging which means you are selling their product but it will have your label on it allowing you to build your own brand of the actual product.

Example: Socking Behaviour

Business Model #4: Drop Ship

In its simplest term, dropshipping allows you to list products on your ecommerce site and sell them but you are essentially selling them for someone else. The order gets passed to the dropshipping supplier who then fulfills and ships the order to your customer on your behalf. Your profit is the difference between what you charged the customer and the price the drop shipper gave you the product at. Usually, with dropshipping your profit margins are slim, around 20%. You definitely need to move a lot of units to make good money with drop shipping but it can be done.

Low Risk: Dropshipping is low risk in terms of potential loss because you never buy inventory up front. Other benefits of drop shipping include:

- No Inventory/Warehouse Costs: Because you aren’t buying any inventory you don’t have to store any inventory.

- No Fulfillment & Shipping: Since your drop shipper deals with all the shipping and fulfillment you don’t need to worry about packing and shipping goods. This is a massive time saver.

When going with a drop shipping business model, you can either work with manufacturers by contacting them directly or you can work with an aggregator. An aggregator works with hundreds of manufacture and makes it easy to sell thousands of types of products without establishing the need to establish thousands of relationships with each individual dropshipper. To find dropshipping suppliers, check out our curated Dropshipping Suppliers Directory.

A word of warning though, although these aggregators make it easier to sell a variety of products, they take a cut of an already slim pie. Additionally, many will make you pay a yearly “membership” or “sign up” fee of a few hundred dollars. You usually can’t even see the products or margins on the products they have to offer until you pay that fee.

Branding Options: Dropshipping involves exclusively selling other brands, thus, the branding capabilities are generally very limited.

So, am I going to make, manufacturer, wholesale or dropship my sock products?

You have probably guessed by now what I plan to do for my sock business. I’m a high risk/high rewards kinda guy and I’m also a branding guy. I prefer to build a brand and I believe in order to really stand out, I will need full control over the product, packaging, and fulfillment to start. Therefore, I will be working with a manufacturer to create my product.

Finding a Manufacturer

I have decided to work with a local manufacturer for this project for a few reasons:

- I Want Better Communication With my Manufacturer vs. Sourcing Overseas: It can be a challenging process to communicate with someone on the other side of the world who speaks a different language. I want to to be able to build a stronger relationship with face to face communication.

- I’m Better at Negotiating in Person: I have already selected the manufacturer I am going to work with and was able to negotiate favorable terms for a minimum order quantity. If I went overseas, I’d have to order a minimum of 1000 pairs per style (likely closer to 2500). This doesn’t work well for limited editions socks, especially when just starting out. Our local manufacturer has agreed to give us a minimum order quantity of only 60 pairs per style!

- Low MOQs Means Lower Startup Costs: The low MOQ of 60 pairs per style allows me to keep my startup costs low.

- No Import Headaches: Not that this is a huge issue but when you import from other countries, there are a few extra steps and processes to set up to get your goods shipped and cleared through customs, like working with a customs broker and freight forwarder.

Finding local manufacturers for my product wasn’t all that hard. This obviously depends on the type of product you choose and where you live but I was easily able to find a half dozen manufacturers within an hour drive of me by doing a few simple searches on Google for local sock manufacturers.

Negotiating With the Manufacturer

It took me a few calls to find a manufacturer that was willing to work with a lower MOQ. Many other manufacturers simply said no. Once I found one that was will to help to discuss details further, I presented to him our unique business model and team. This gave him the confidence needed to help us out and agree to a lower price than he would traditionally charge plus higher quality material, and even lower MOQ’s.

Some tips on negotiating with a manufacturer:

- If you are going to work with a local manufacturer, call them, don’t email. You can get a lot more accomplished in one quick phone call then you can with a dozen emails.

- Meet with them as soon as possible: Let them put a face and a handshake to the pitch you gave them on the phone. It helps build confidence and a relationship between partners.

- Pitch your business and yourself: Have a pitch ready. What is your business, how are you different, how can you help them, and what is your experience. All these things helped my selected manufacturer feel better about working with me and giving me a very fair deal.

The Next Steps

My next step which I am already working on involves creating the socks designs for our first series and getting those to out manufacturer. Production will actually take about 8 weeks because we are using a higher quality cotton material compared to what our manufacturer currently uses and has in stock. Because of this, they will have to dye the material first before the socks can be produced.